Mikro-Spritzguss

Komponenten-Technologien

Micro Molding

As medical devices push the boundaries of anatomical access, miniaturization is essential across components and subassemblies. Traditional injection molding has long been a cornerstone of medical manufacturing, but as devices shrink, the need for precision micro molding has emerged.

At Nissha Medical Technologies, micro molding is a core capability, enabling the cost-effective production of highly intricate, ultra-small components with exceptional accuracy. Whether for complex geometries or critical dimensional precision, our expertise ensures that even the smallest parts meet the highest performance standards.

Weniger invasive Geräte durch extrem dünnwandiges Spritzgießen

- Präzision, die Mikro-Funktionalität für medizinische Technologie-Fortschritte auf kleinstem Raum ermöglicht

- Echte Miniaturisierung – kleiner als ein Harzpellet

- Erfolgreiches Füllen von Strömungslängen mit hohem Aspektverhältnis

- Spritzguss mit praktisch keinem Formschräge & unvorstellbar engen Toleranzen

- Montagetoleranzgenauigkeit von +/- 1,5 Mikrometern

- Funktionale Oberflächentechnologie

- Mikrobohrungen, Mikrofluidik, echte scharfe Kanten und Mikrobarben

- Bauteile bis zu 7 Zoll (177,8 mm) mit Mikrostrukturen, dünnen Wänden, komplexen Geometrien und/oder engen Toleranzen

Micro Molding Processes

Bioresorbable & Long-Term Implantable Molding

Fluoropolymer Molding

Two-Shot, Overmolding & Insert Molding

- Less invasive devices through extreme thin wall molding

- Precision that enables micro functionality for medical technology advancements in small scale space

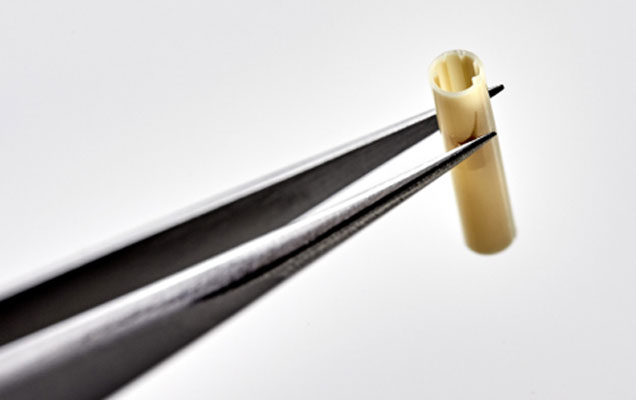

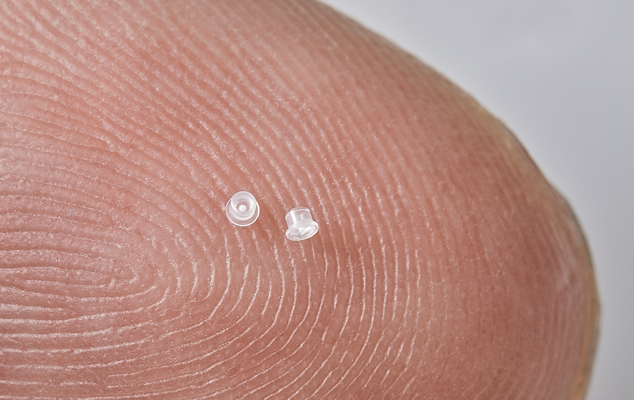

- True part miniaturization – smaller than a pellet of resin

- Successfully fill high aspect ratio flow lengths

- Molding with virtually no draft & unimaginable tight tolerances

- Assembly positional accuracy of +/- 1.5 microns

- Functional surface technology

- Micro holes, microfluidics, true sharps, and micro barbs

- Parts up to 7” (177.8mm) with micro features, thin walls, complex geometries and/or tight tolerances

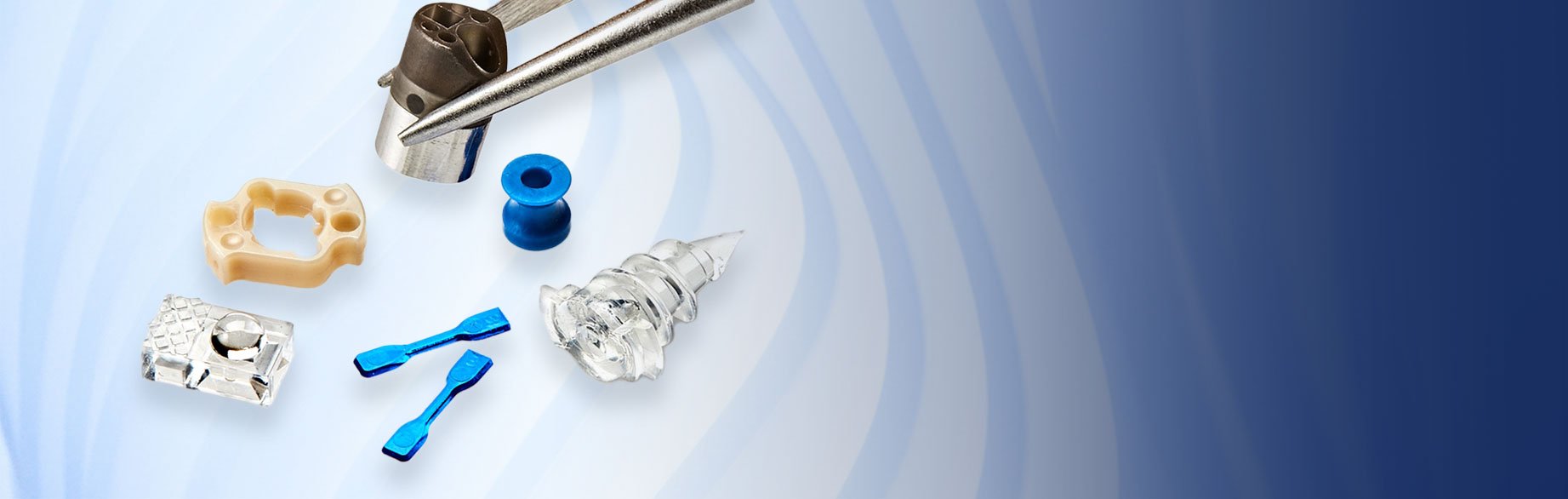

Examples of

Our Micro Applications

- Microfluidics

- Catheter Tips (thinnest on the market)

- Micro Optics

- Connectors

- Litigating Clips

- Body Sensors

- Microneedles/Barbs

- Microarray Patches (MAPs)

- Suture Anchors

- Hydrocephalus Pumps

- Bioresorbable Anchors

- Long-Term Implantable Anchors

- Drug Delivery

- Fluid Testing

- Tissue Repair

- Surgical Tools

- Dental Implants

- In Vitro Devices

- Stents

Advantages and Capabilities

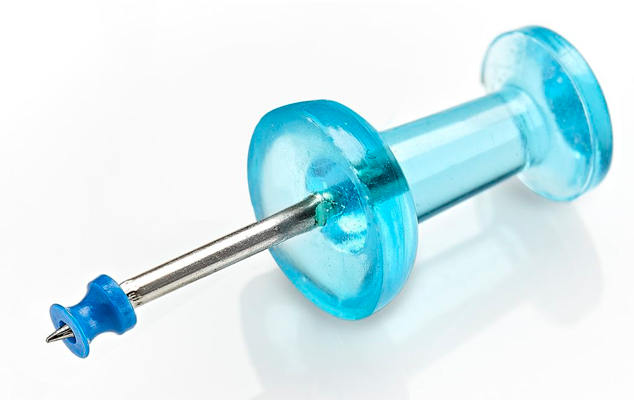

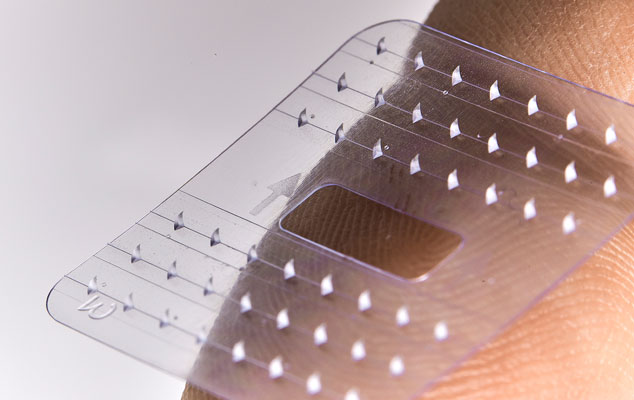

Thin Wall and Long Aspect Ratio Parts

Precision micro molding allows for wall thicknesses as thin as 0.001" and aspect ratios up to 400:1. These parts are engineered for strength, flexibility, and performance in demanding medical and drug delivery applications.

Uses:

- Drug Delivery

Multi Shot Parts & Two Shot Molded Parts

Two-shot molding combines different materials or colors into one micro part for added functionality or simplified assembly. This technique is ideal for seals, gaskets, overmolded features, and geometries that are too complex or delicate for manual handling.

Uses:

- Minimally Invasive Surgical Devices

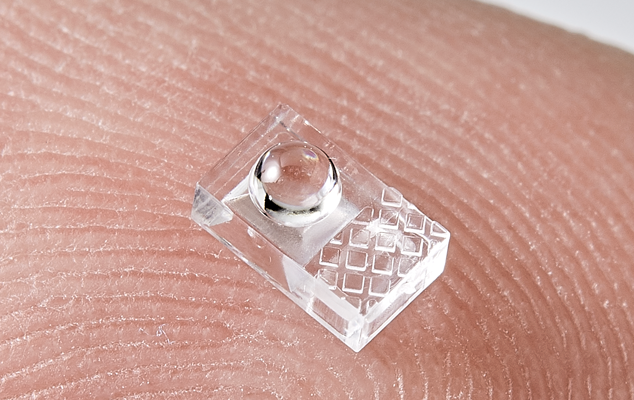

Parts for Optics

Micro injection molded components engineered for optical clarity and precision—ideal for guiding lasers, lenses, and light through highly sensitive medical and diagnostic devices.

Uses:

- IOL (Interocular Lens)

Parts with Slides/Undercuts

Micro molds use side actions, lifters, and collapsible cores to form undercuts, internal threads, and other trapped features that cannot be ejected straight. This enables complex geometry in one shot with reliable ejection and repeatable tolerances.

Uses:

- No specific uses, very common in all micro molded components

Extreme Small Parts

Micro molded parts can be as small as a dust speck and still meet tight tolerances for critical medical and drug delivery applications. These ultra-miniature components often enable the entire device’s performance and functionality.

Uses:

- No specific uses, very common in all micro molded components

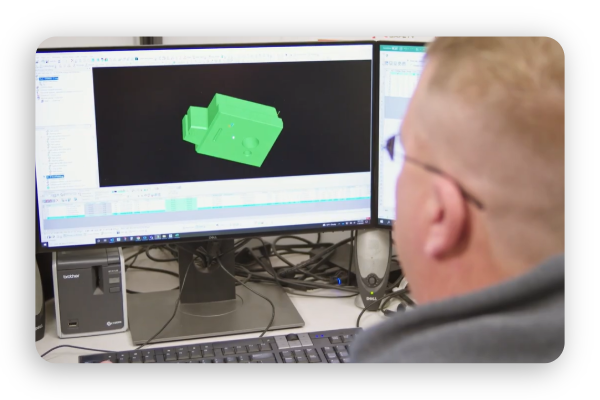

Plan, Plan, Plan, Execute

- Internally developed Microns Matter® PFMEA Risk Assessment Strategy

- State-of-the-Art Equipment

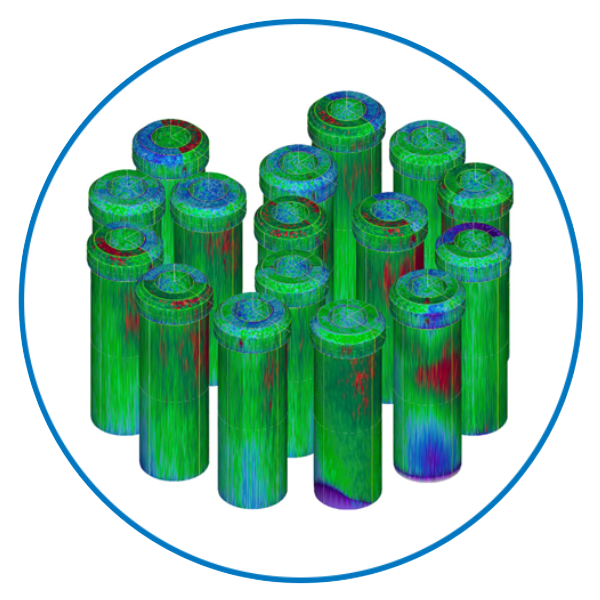

- CT Scanning

- DfM, DfX, and DfA Analysis

- Mold-Flow Analysis

- Micro Application Expertise

- Root Cause & Failure Mode Analysis

- IQ/OQ/PQ Validation

- Micro Injection Mold Design & Fabrication

- Robust Process Development

- Micro Automation Design & Fabrication

Micro Project Success

from the Start

We offer expertise at every stage of the design-to-manufacturing process. Whether your application requires multiple materials for the most intricate over-molded component, a tiny medical implant, or a microfluidic chip with a minuscule micron tolerance, we have the materials, complex feature knowledge, experience, and understanding to achieve success.

Explore our other Micro Solutions

Our mission is to provide world-class micro solutions that save and improve lives.

Bereit, loszulegen?

Wir können helfen!

Unser Team steht bereit, um Sie bei Ihrem nächsten Projekt zu unterstützen.

Kontaktieren Sie uns noch heute!

Globale Zentrale

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com