Isometric Micro Molding

Component Technologies

Isometric Micro Molding

The largest medical-focused micro molder in the US

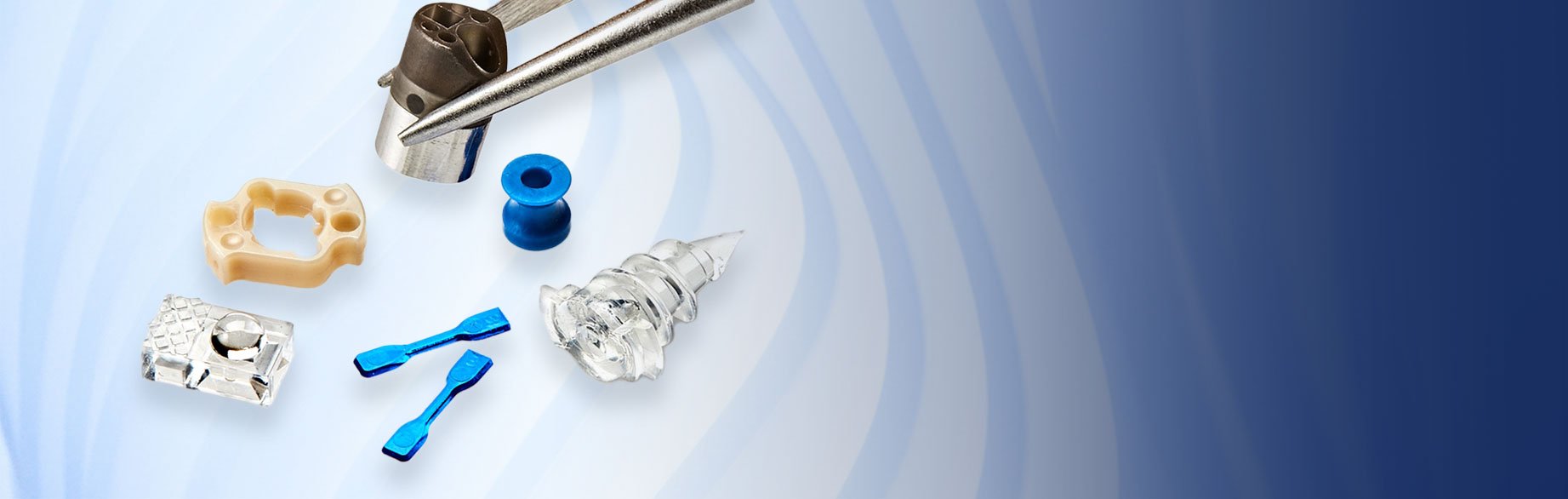

As medical devices push the limits of anatomical access and minimally invasive techniques, miniaturization across components and subassemblies is more critical than ever. Traditional molding methods often fall short when dimensional accuracy, complex geometries, and ultra-small features are required.

When it comes to micro molding, especially for high-precision markets such as medical and drug delivery devices, it’s critical to choose a partner with industry experience. With 36 years of experience and over 1,000 completed projects, Nissha Medical Technologies delivers precision-molded components that meet tight micron-level tolerances, including thin walls, micro holes, and high-aspect-ratio features.

Our vertically integrated approach allows us to design, tool, mold, and assemble complete micro solutions in-house, ensuring greater speed, reliability, and performance for every project. Nissha Medical Technologies provides complete end-to-end solutions for high-precision component design and micro mold manufacturing for micro-sized parts to larger parts with micro features, thin walls, complex geometries, micro holes, and/or tight tolerances.

Markets

- Diagnostics

- Medical/Drug Delivery

- Micro Electronics

- Microfluidics

- Optics

- Wearable Technology

Materials Expertise

- Thermoplastic Resins

- Bioresorbable

- Fluoropolymers

- Liquid Silicone Rubber (LSR)

- Long Term Implantable

Micro Applications

- Cannulas

- Catheter Tips

- Intraocular Implants

- Litigating Clips

- Micro Gears

- Micro Optics

- Microarray Patches (MAPs)

- Microfluidics

- Microneedles & Barbs

- Transdermal Patches

Micro 3D Printing

- Parts in hand within 2 days to 1 week

- Crucial support for customers during project development

- Print multiple designs to compare side by side in addition to mating parts for assembly

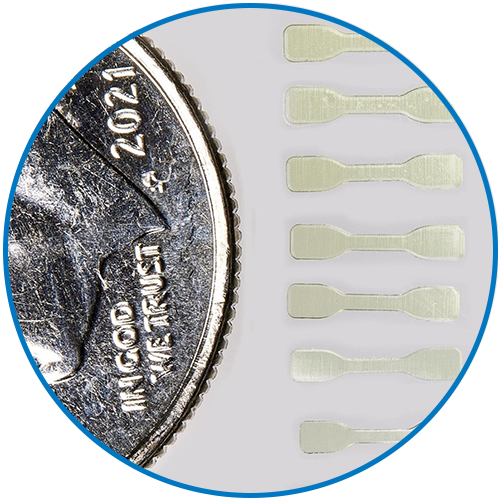

- Feature sizes down to 2 microns

- Micro 3D printed molds

Micro Tooling

- THE Enabling factor

- In-house state-of-the art precision machining and submicron tool building capabilities

- Dedicated tool building facility with 50+ toolmakers supporting creative tool design and scalability

Micro Molding

- Molding all thermoplastics, long-term implantable, bioresorbable, fluoropolymers, and liquid silicone rubber (LSR)

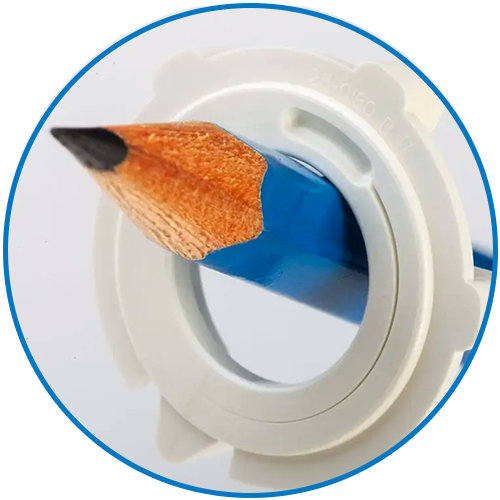

- High volume micro manufacturing of parts up to 7" with micro features/tight tolerances

- Thin wall, microfeature, micro-sized, tight tolerance, insert molding, over-molding, and 2-shot molding components

Micro Automated Assembly

- Fully automated and integrate micro assemblies and devices

- Ability to maintain the datum structure of molded parts from the mold and into the assembly

- Micron positional accuracy (+/- 1.5 microns) to laser weld, ultrasonic weld, resistance test, form, assemble, epoxy, and packaging

- In-line vision inspection and industry 4.0 data output

- Manufacturing micro components and sub-assemblies for high volume applications

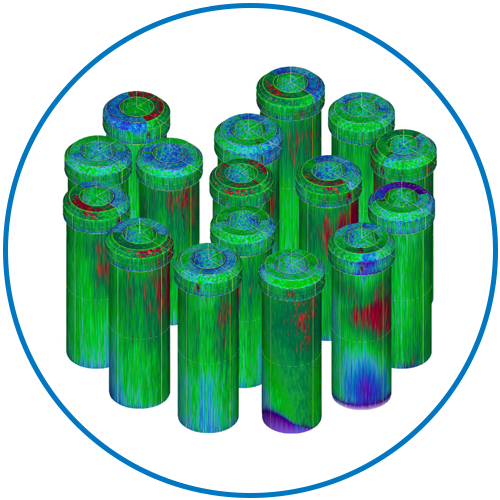

CT Scanning

- 360⁰ three-dimensional point cloud compared to the intended CAD model

- Color deviation plots show variations in all axes at the micron level

- Utilizes CT Scanning from DOE to part validation and through high volume manufacturing

- Instant dimensional feedback while the mold process is being developed

COMPONENT TECHNOLOGIES

Leveraging advanced technologies, the Nissha Medical Technologies team assists medical OEM’s to advance in their respective markets. Areas of specialization include Surgical Navigation, Surgical Robotics, and Advanced Sensing Applications.

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com