CT Scanning

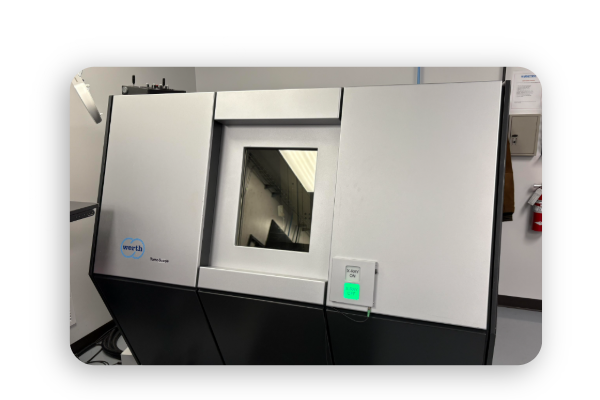

In-house, high-resolution, CT scanning capability.

CT Scanning

Immediate Alignment of Process Variables to Critical Attributes

At Nissha Medical Technologies, precision is central to everything we do. It’s vital, then, that we use our in-house, high-resolution, CT scanning capability to validate that the design intent is always achieved.

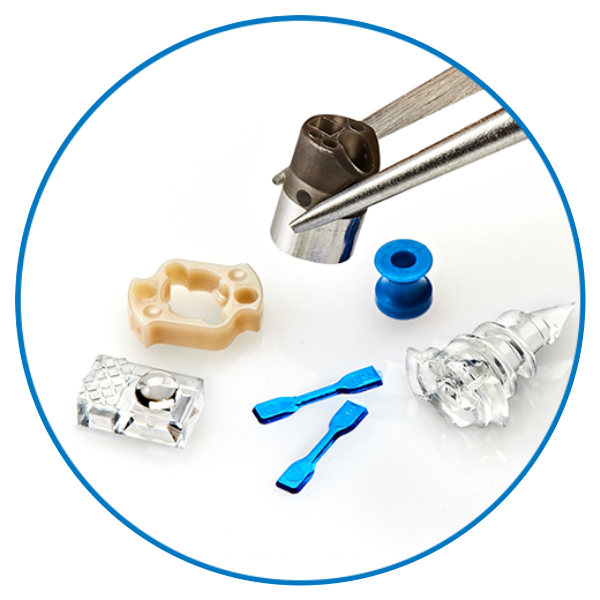

CT scanning is a core pillar of micro molding because it offers complete visibility into features traditional metrology tools simply can’t reach. At the micron scale, internal features, bond lines, or trapped geometry can’t always be probed or sectioned without damaging the part. CT scanning solves this by producing a dimensional, non-destructive 3D reconstruction of every critical attribute—both internal and external.

Through CT scanning, we can detect deviations in the actual molded or assembled part against the original 3D CAD design data at the micron level in all axes. In addition, CT scanning assists with Metrology and Gage R&R. These systems are perhaps the most challenging aspects of micro molding, where it is common to have more error in the measurement than in the actual parts.

- Capture: Thousands of 2D grayscale projections are recorded as the part rotates 360°.

- Reconstruct: Advanced algorithms convert these projections into a voxel-based 3D model.

- Evaluate: Engineers inspect internal geometry, wall transitions, interfaces, and voids invisible to conventional tools.

Why Choose NMT?

- More than a decade of production-level CT scanning experience, including applications dating back to 2014.

- Use of CT scanning for both development and ongoing production inspection, which is uncommon in the industry.

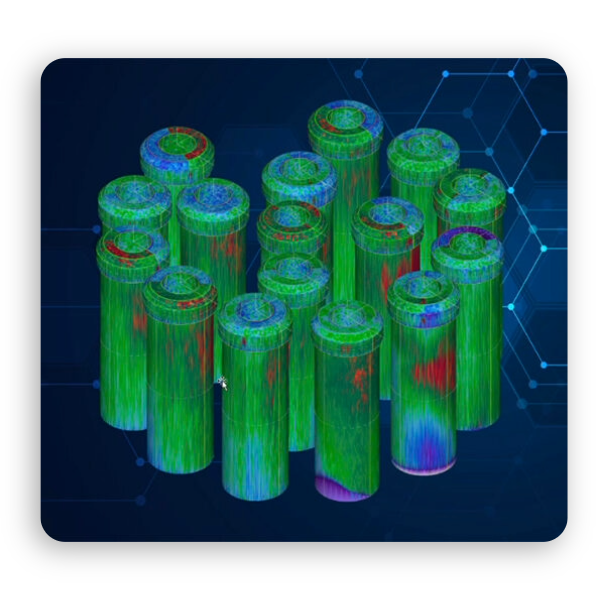

- Ability to scan 16–20 micro molded parts at a time, improving statistical confidence and reducing inspection time.

- Digital retains stored for every scan since CT adoption, allowing true year-over-year comparisons without rescanning physical parts.

- Tool wear monitoring via multi-year data overlays, helping detect mold degradation earlier.

Expanded Advanced Services

- Non‑Destructive Failure Analysis: Identify failure modes in devices without sectioning or disassembly, preserving evidence and reducing investigation time.

- Reverse Engineering & CAD Reconstruction: Scanning parts without existing CAD to generate accurate 3D models for legacy components or competitive analysis.

- Virtual Datum & Fixture Simulation: Leveraging software tools to simulate datum structures and inspection setups digitally, including material-based deformation using Poisson’s ratio.

- Third‑Party / Contract CT Inspection: Offering CT scanning as an independent, third-party inspection service, including batch scanning for customers who need unbiased internal analysis, validation support, or additional inspection capacity.

Benefits

- Non-contact, non-fixtured metrology (eliminates datum errors)

- Handles complex multi-axis datum structures

- Assembly and multi-cavity stack-up tolerance analysis

- Competitive device comparison

- Confirms design intent

- Digital retains that do not impact shelf life

- 10–20 minute 3D FAIR

- Supports DOE process development

- Full internal view of parts

What CT Scanning Helps Detect

- Internal voids or trapped gas bubbles

- Distortion in thin-wall channels or tubes

- Snap-fit or undercut fill issues

- Resin-flow–related deformation

- Assembly alignment, clearance, or interference points

- Humidity or environmental sensitivity in hygroscopic materials

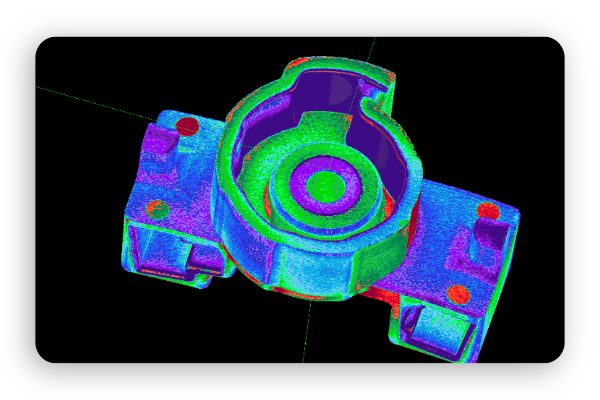

Color Maps

and Point Clouds

Our engineers analyze each scan using color-deviation maps that compare the part directly to the CAD model. This immediately highlights high spots, sink areas, or thin sections. Millions of measurement points form a tessellated point cloud, ensuring no feature is overlooked.

Explore our other Micro Solutions

Our mission is to provide world-class micro solutions that save and improve lives.

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com