Micro Tool & Design

Delivering Submicron Precision Through Advanced Micro Tooling

MICRO TOOL & DESIGN

THE Enabling Technology to Micron Tolerances

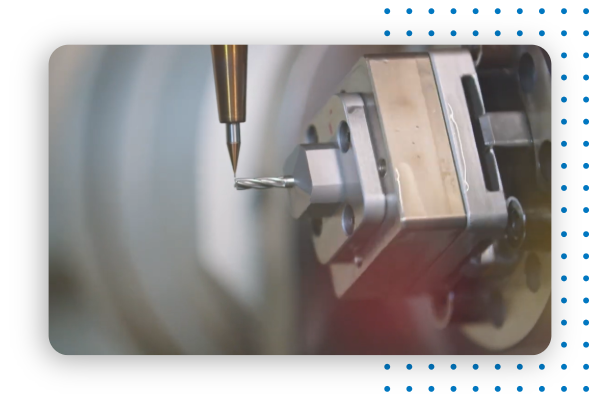

Nissha Medical Technologies has 36 years of experience at their Isometric Micro Molding Center of excellence, especially in the ultra-precision mold building industry. Over the decades, NMT - New Richmond has regularly been the “go-to” partner for high-risk/high complexity projects.

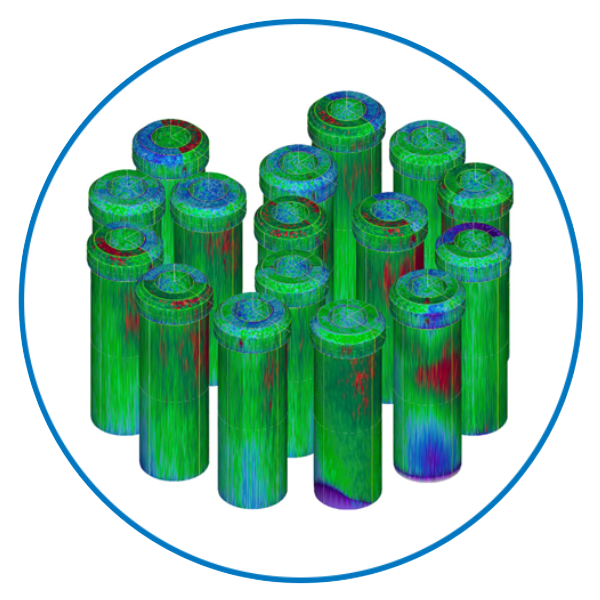

Nissha Medical Technologies - New Richmond has submicron precision tool building capabilities, which allows us to create micro features and venting needed to successfully mold and validate the final part or assembly. We achieve these specifications through our state-of-the-art precision machining, which provides a level of unmatched sophistication.

Our in-house technologies deliver reliable micro-cutting tools with superior accuracy and finish.

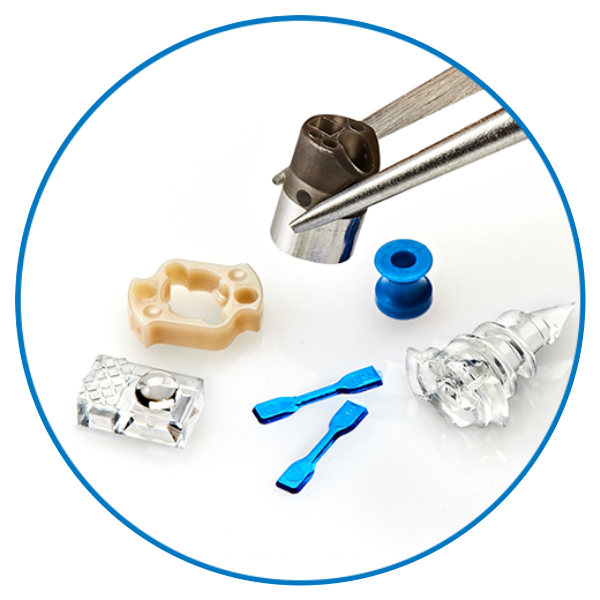

Micro Tooling

Feature Examples:

- Tooling for parts with a total part weight of 0.0004 grams and up

- Profile and positional accuracy to single microns (0.00004″)

- Precision threads/gears to micron tolerances

- Wall thickness as thin as 0.001″ (0.04mm)

- Mold core diameters as small as 0.002″ (0.05mm)

Prototype to Production Molds

- Prototype modules to support design verification and initial part needs

- Production multi-cavity molds

- Molds maintained by the same journey tool makers that fabricated them

Explore our other Micro Solutions

Our mission is to provide world-class micro solutions that save and improve lives.

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com