Micro Automation

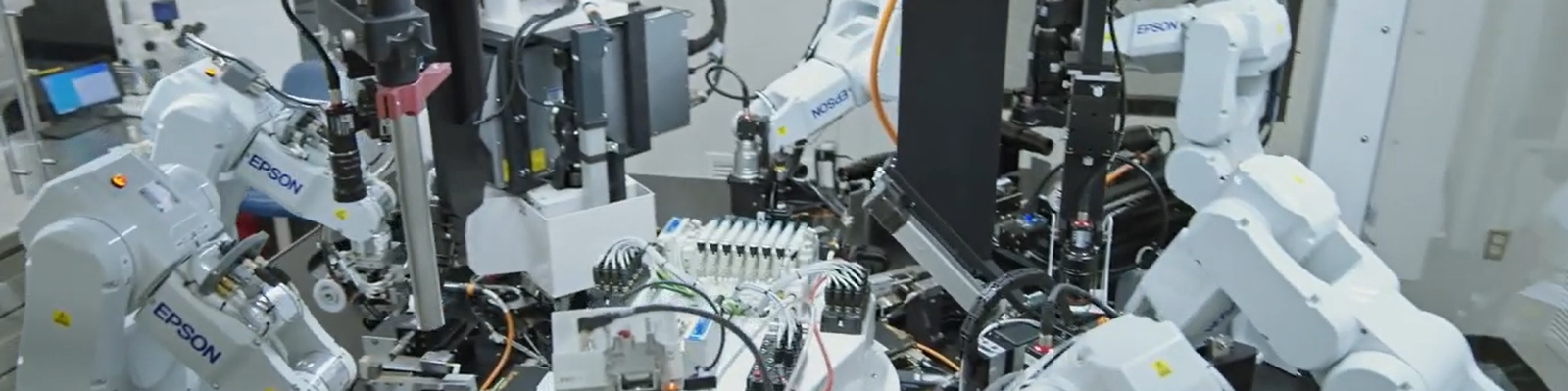

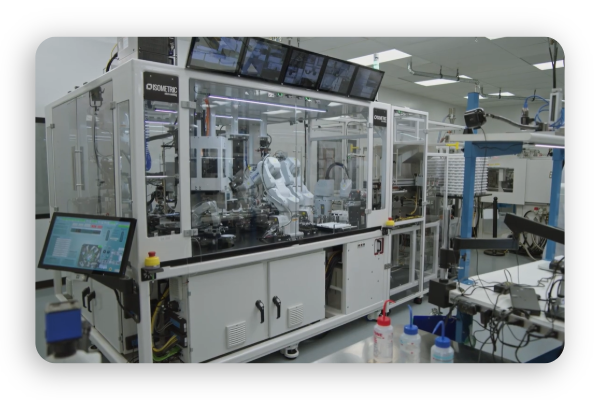

Our fully automated systems are designed and fabricated in-house

MICRO AUTOMATION

IN-HOUSE, WORLD CLASS MICRO AUTOMATED ASSEMBLY

In today’s high precision markets, it’s important to use automated assembly solutions for successful micro-manufacturing projects. Micro automated assembly reduces damage, bioburden, handling, labor, scrap, and the need to regain positional datum structure.

At the micro level, manual assembly is cost-prohibitive and requires a level of dexterity that makes it impossible to avoid significant, unacceptable errors for micron tolerances. This is critical, especially when the key objective with micro automated assembly is to reduce the number of times a part is handled.

Over 15 years of Experience

In Micro Automation and Assembly

Nissha Medical Technologies has developed discrete, ultra-precision capabilities in the automated assembly of micro medical devices, as well as drug delivery devices. NMT’s in-house, micro automated assembly provides single micron positional accuracy combined with our in-depth understanding of micro assembly methodology.

Fully automated systems are

designed and fabricated in-house:

- Integration of PLC logic

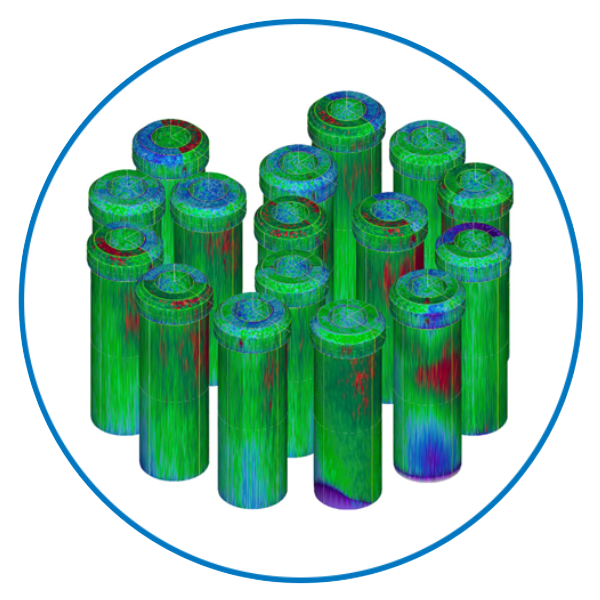

- Inline vision inspection systems–100% part inspection/risk-mitigation

- Micro dispensing

- Solvent bonding

- UV curing

- Inline pressure decay leak testing

- Laser welding

- Ultrasonic welding

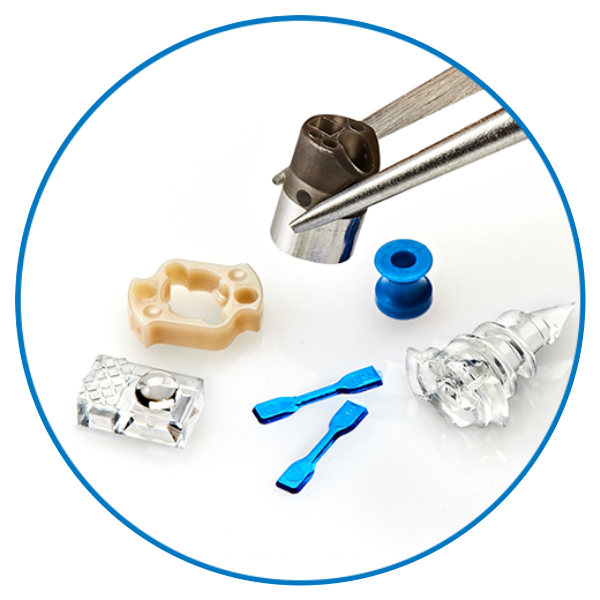

- Assembly of metal, filter mesh, wires, cables, and other plastic parts

- Industry 4.0 data collection and sharing

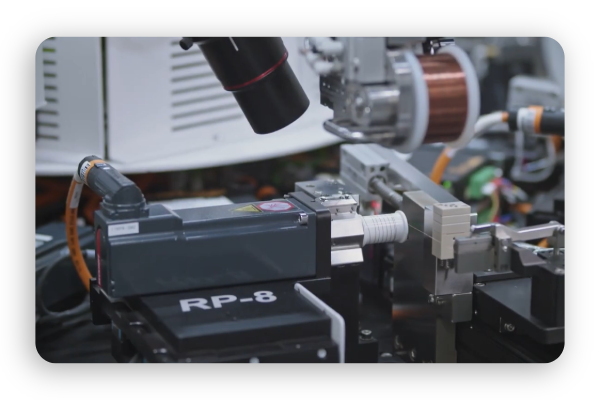

System Features

- Pneumatic or servo actuated

- Fool-proof laser safety systems

- Touchscreen machine controls

- Data capture and storage systems

- Networking to manufacturing plant IT systems

- Precision function controls ± 0.0001″ (0.0025 mm)

- Nano precision components to 0.00004″ (1 micron)

- Pick and place equipment

Custom Micro Automation

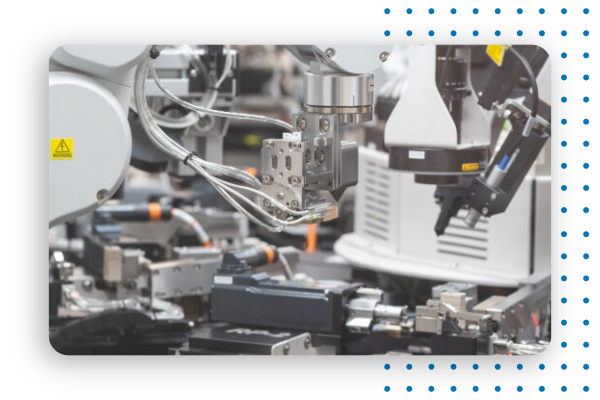

- Precision self-contained semi and full automated assembly cells

- Single and multi-station assembly, test, and inspection systems

- Integrated clean rooms built to specified class

- Benchtop assembly fixtures and handheld devices

- Ultra-precision bonding and fastening operations

- Automated micro-machining cells (0.0025 mm)

- EOAT’s to protect molded parts and prevent mold damage

- Datum errors reduced if enabling part is held and re-positioned the least amount of times

- Delicate parts can be protected by other parts in the sub-assembly

Explore our other Micro Solutions

Our mission is to provide world-class micro solutions that save and improve lives.

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com