Nissha Medical Technologies follows a structured stage gate process to guide every project from concept to commercialization. Each phase builds on the last, with defined checkpoints to confirm feasibility, design performance, and manufacturing readiness. This ensures we reduce risk, capture feedback early, and accelerate time-to-market.

Step 1

Learning & Observation

- Understand User Needs

- Observe Environment

- Create Knowledge Database for the Entire Team to Share

- Analyze Gathered Data

- Define Initial Customer Requirements

Step 2

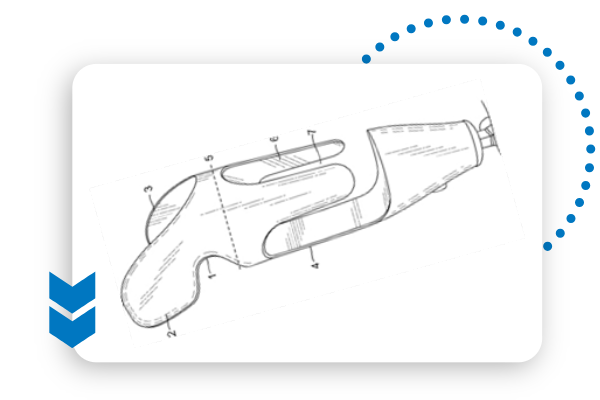

Brainstorming & Visualization

- Form a Multidisciplinary Team and Keep Users Involved in Collaboration

- Brainstorm and Generate Multiple Concepts

- Create Sketches, Physical Mock-Up and Ergonomic Prototypes

- Fail Quickly to Accelerate Learning

- Concurrent Business and IP Analysis

Step 3

Engineering & Development

- From Concept to Commercialization

- Wearable, Surgical, Mechanical and Electro-Mechanical Devices

- Experience With Class I – III Devices

- Design for Excellence (DFX)

- Cost

- Manufacturability

- Quality

- Sustainability

Step 4

Verification & Validation

- Extensive Functional Bench-Top Testing

- In-vitro, In-vivo and Cadaveric Evaluations

- Rigorous Verification Testing

- Define Test Methods and Equipment

- Demonstrate That Outputs Meet Inputs

- Refer to Risk Analysis to Determine Appropriate Sample Size and Confidence Levels

- Document Results in a Detailed Report

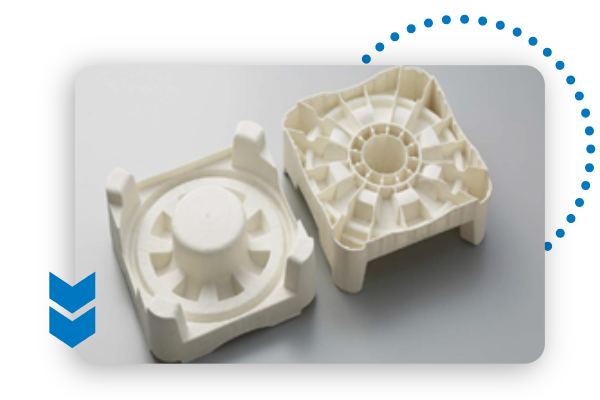

Step 5

Pilot Manufacturing Ramp-Up

- Production Tooling

- Process Development and Validation

- Production Documentation Including Travelers, Work Instructions, Etc.

- Process Control, Qc and Incoming Inspection

- Pilot Production

- Release to Manufacturing

Step 6

Commercial Production

- Tray Sealing, Pouch Sealing, FFS

- Packaging Development & Prototyping

- Packing Design Verification

- Sterility Validation

- Test Lab

- Package Integrity

- Burst and Creep Testing

- Dye Penetration

- Measurement Analysis

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com