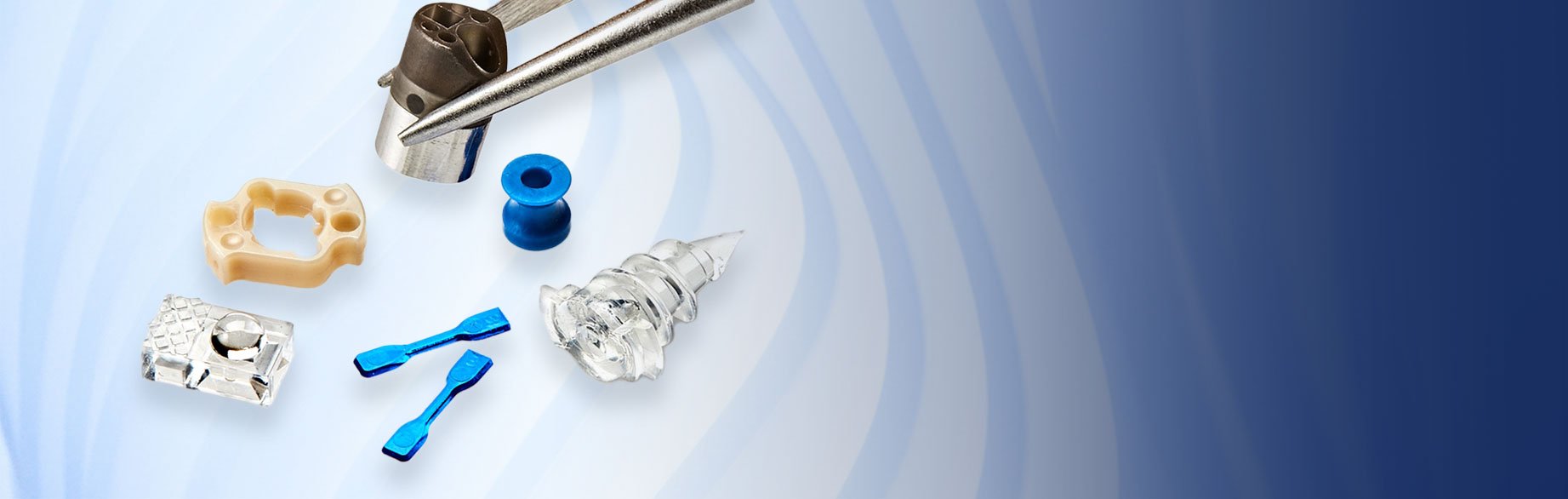

Cannula Molding

Cannula Molding

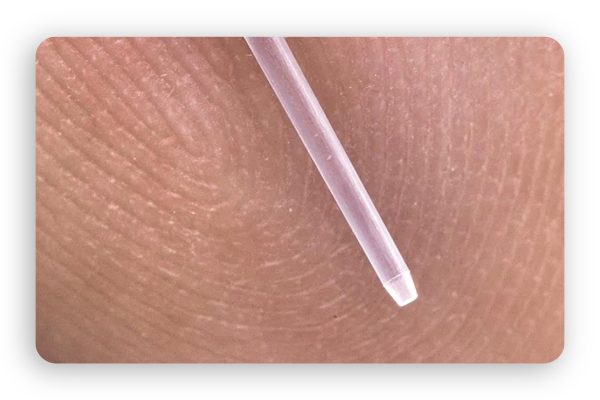

Historically, micro-cannula manufacturing has relied on extrusion, followed by multiple secondary steps—such as tipping, cutting, bonding, and shaping. Each of these stages introduces potential variability and can constrain both efficiency and design options.

Nissha Medical Technologies, utilizing Isometric Micro Molding technologies has introduced a transformative approach: the production of fully molded microcannulas with customizable distal and proximal ends thereby eliminating the need for any secondary operations. By addressing complex challenges like core pin stability, optimized venting, and ultra-high-precision material flow, Isometric has established a new benchmark for the industry. As a result, original equipment manufacturers (OEMs) can now benefit from greater cost efficiency, expanded design flexibility, scalable production capabilities, and enhanced device reliability.

Cannula Applications

Insulin Delivery

Systems

Continuous Glucose Monitors

Drug

Infusion

Microfluidics and Minimally Invasive Diagnostic Devices

- Uniform wall thickness

- Reliable tip geometry

- Predictable flow paths

- High yields

Our Breakthrough:

Fully Molded Cannulas

We mold the entire cannula, including the distal tip, in one process. This matters because it:

- Removes variability created during tipping and reshaping

- Ensures the lumen stays centered through core pin stability

- Enables geometries and features extrusion cannot achieve

This capability is possible through expertise in sub-micron precision tooling, core pin stability, venting, pressure control, and micro-scale material flow

What This Means for OEMs

Higher Reliability

Consistent wall thickness, better tip integrity, and fewer defects.

Lower Cost

No secondary processing. No multi-step supply chain. Fewer inspections. Higher yields.

More Design Flexibility

We can mold connectors, funnels, and other features directly onto the proximal end, eliminating the need for bonded components and opening new device design possibilities.

Scalable Production

Precision that is repeatable at volume even with ultra-thin, complex geometries.

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com