Isometric Micro Molding

Component Technologies

Isometric Micro Molding

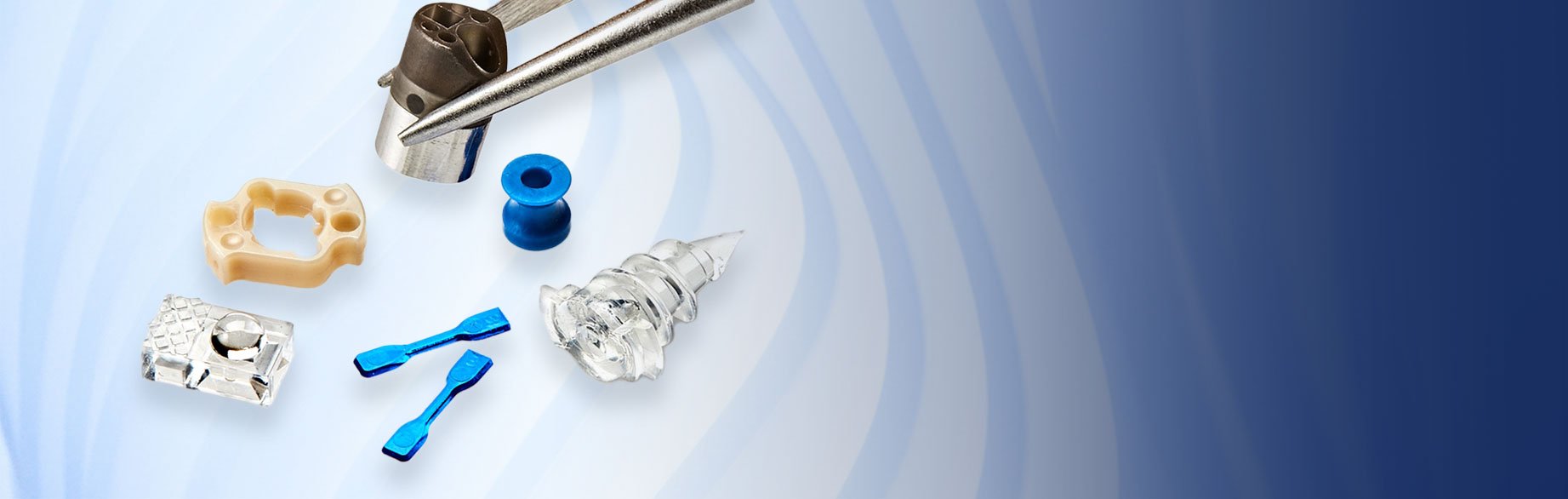

As medical devices push the boundaries of anatomical access, miniaturization is essential across components and subassemblies. Traditional injection molding has long been a cornerstone of medical manufacturing, but as devices shrink, the need for precision micro molding has emerged.

At Nissha Medical Technologies, Isometric micro molding is a core capability, enabling the cost-effective production of highly intricate, ultra-small components with exceptional accuracy. Whether for complex geometries or critical dimensional precision, our expertise ensures that even the smallest parts meet the highest performance standards.

Isometric Micro Manufacturing Capabilities

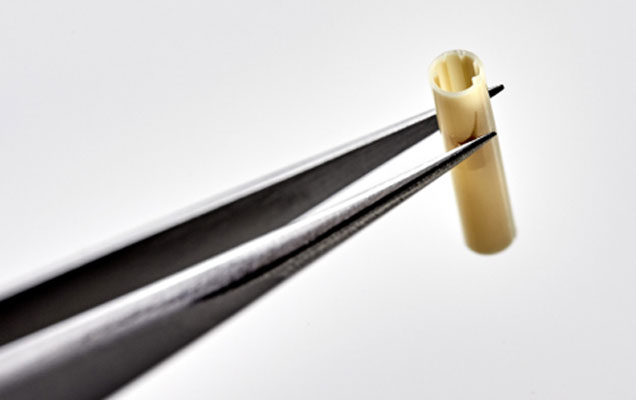

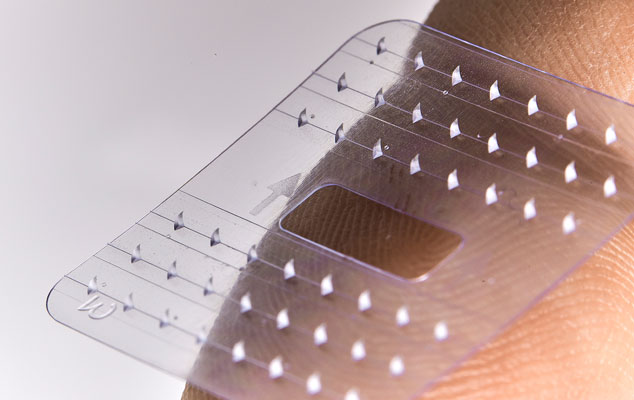

- Less invasive devices through extreme thin wall molding

- Precision that enables micro functionality for medical technology advancements in small scale space

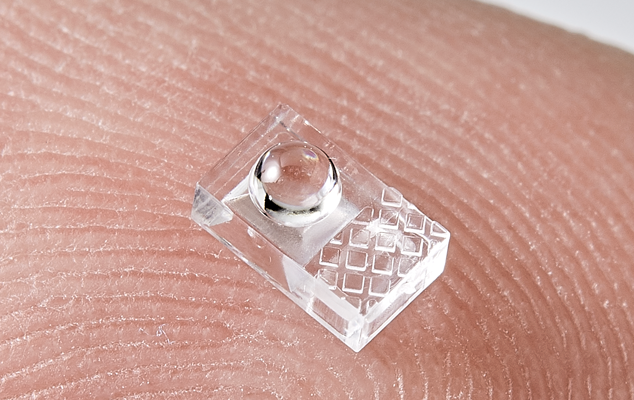

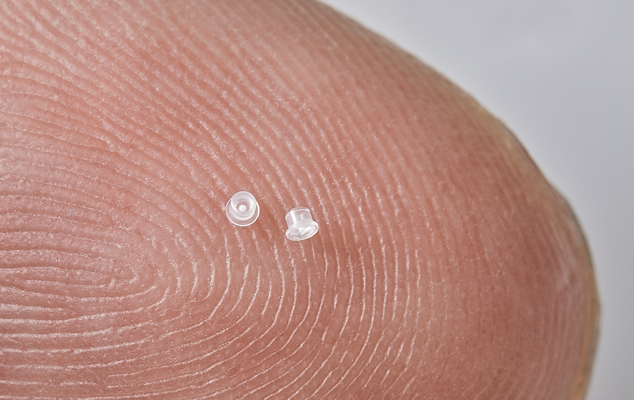

- True part miniaturization–smaller than a pellet of resin

- Successfully fill high aspect ratio flow lengths

- Molding with virtually no draft & unimaginable tight tolerances

- Assembly positional accuracy of +/- 1.5 microns

- Functional surface technology

- Micro holes, microfluidics, true sharps, and micro barbs

- Parts up to 7” (177.8mm) with micro features, thin walls, complex geometries and/or tight tolerances

Advantages and Capabilities

Thin Wall and Long Aspect Ratio Parts

Multi Shot Parts & Two Shot Molded Parts

Parts for Optics

Parts with Slides/Undercuts

Extreme Small Parts

Nissha Medical Technologies aims to be a visionary partner in transforming surgical care.

We achieve this by:

| Collaboration: Actively partner with physicians, hospitals, entrepreneurs, academics, and OEMs to leverage diverse expertise and navigate the complexities of technology integration. |

|

| Proactive Approach: Invest in emerging technologies like miniaturization, surgical visualization, and steerability to stay ahead of the curve and develop scalable solutions for the evolving healthcare industry. |

|

| Focus on Patient Care: Everything we do revolves around improving patient outcomes. We want to identify unmet needs and integrate advanced technologies to enhance bedside care, ensuring their innovations have a direct impact. |

|

| Seamless Integration: Excel at integrating these advancements into our existing infrastructure, allowing for faster commercialization of next-generation surgical tools. |

|

| Commitment to Quality: Ensure our solutions meet the highest standards by incorporating groundbreaking technologies like innovative steering for minimally invasive surgery. |

Ready to get Started?

We can Help

Our team is standing by to help you with your next project! Contact us today!

Global Headquarters

400 Exchange Street. Buffalo, NY 14204

P: +1.800.893.6361

E: dm.info@nisshamedical.com

E: dm.orders@nisshamedical.com